Spectrus NX1102

Spectrus NX1102 is a microbial control agent approved for use in a variety of industrial water-based systems. Spectrus NX1102 contains 20% of the active ingredient, 2,2-dibromo-3-nitrilopropionamide (DBNPA).

Spectrus NX1102 - Microbiological Control Agent

- Potent, rapid acting antimicrobial

- Organo-bromine based

- Produces a total halogen residual

- Minimal environmental impact

- Approved for once-through cooling

- Approved for non-potable RO units

- FDA approved (CFR 176.300)

- USDA approved (G-5, G-7)

- Approved for sale in California

DESCRIPTION AND USE

Spectrus NX1102 is a microbial control agent approved for use in a variety of industrial water-based systems. Spectrus NX1102 contains 20% of the active ingredient, 2,2-dibromo-3-nitrilopropionamide (DBNPA).

This product is most effective as a bactericide, but will also control fungi and algae when used at higher dosages.

Spectrus NX1102 aids in the control of bacterial, fungal, and algal slimes in evaporative condensers, heat exchange water systems, commercial and industrial cooling towers, influent systems, industrial water scrubbing systems, and brewery pasteurizers. It is also registered for use in once-through and closed cycle systems, as well as industrial air washer systems equipped with mist eliminators. Spectrus NX1102 can also be used to control microbial fouling of non-potable reverse osmosis equipment.

Control of microbiological populations in industrial water systems is essential to prevent biofouling. In cooling systems, biofouling of heat exchange equipment and tower fill reduces heat transfer efficiency and can force unscheduled shutdowns and extended turnarounds, leading to lost production. Biofouling can influenced corrosion (MIC). As a result of these effects, biofouling must be prevented in order for operating units to achieve profitability goals.

Biofouling in cooling systems can provide an ideal environment for proliferation of Legionella bacteria, the cause of Legionnaires’ disease. Halogens have been recommended by various agencies (CTI, ASHRAE, CDC, etc.) as an integral part of Legionella Risk Reduction programs. Spectrus NX1102 provides a significant halogen residual that can be measured with a standard total chlorine test. The DBNPA active in Spectrus NX1102 is highly effective against Legionella bacteria under laboratory test conditions.

This does not, however, guarantee eradication of Legionella or disease prevention. Chemical treatment alone will not be effective in reducing health hazards associated with Legionella bacteria. System design and location, maintenance practices and employee awareness are critical elements of a successful risk reduction program.

Alternating feed of Spectrus NX1102 with another microbiological control agent (e.g. a Spectrus NX biocide product or a Spectrus BD biodispersant) will provide better control by enhancing biocide penetration of biofilms, by reducing selection of resistant organisms and by aiding cleanup of biofouled surfaces.

ENVIRONMENTAL CONSIDERATIONS

Spectrus NX1102 acts rapidly to control microorganisms, then naturally hydrolyzes to compounds of much lower toxicity. Both high pH and high temperature speed this natural detoxifying process. Figure 1 can be used to determine the half-life of Spectrus NX1102 if the pH and temperature of the treated water areknown. In addition, Spectrus NX1102 can be quickly deactivated with either sulfide ion or sulfite ion. Each ppm (mg/L) of Spectrus NX1102 (0.2 ppm (mg/L) active DBNPA) requires either 0.2 ppm (mg/L) sodium sulfide (0.08 ppm (mg/L) sulfide ion) or 1.0 ppm (mg/L) sodium sulfite (0.6 ppm (mg/L) sulfite ion) for its deactivation.

TREATMENT AND FEEDING REQUIREMENTS

Spectrus NX1102 may be fed continuously or shot-fed to the system. Correct treatment levels and frequency of Spectrus NX1102 addition depend on may factors. These include, but are not limited to, system cleanliness, types of microbes, nutrient concentrations, temperature, pH, retention time, and other system operating characteristics. Consult the product label for general dosage guidelines. Microbiological monitoring is recommended to evaluate product requirements. Consult your GE Betz representative for technical advice on your specific application. In all cases, this product must be applied in accordance with use instructions on the Spectrus NX1102 label.

Feed Point – Apply Spectrus NX1102 to a point in the system where turbulence and flow patterns assure good mixing with the water being treated.

Dilution – This blended product is best fed neat (undiluted) from the storage container.

Compatible Materials – Spectrus NX1102 is compatible with most plastics, fiberglass, ceramic, and Teflon® lines and feed equipment, as well as equipment lined with these materials. Typical materials for use include polyethylene, polypropylene, polyvinylchloride (PVC), Viton, and fiberglass reinforced plastic (FRP).

Avoid: Mild steel, 304, 316, and 316L Stainless Steel, Hastalloy 825, Carpenter 20, Nickel 200, aluminum, copper, and brass.

GENERAL PROPERTIES

Physical properties of Spectrus NX1102 are shown on the Material Safety Data Sheet, a copy of which is available on request.

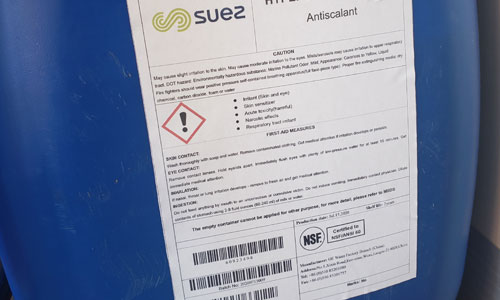

PACKAGING INFORMATION

Spectrus NX1102 is a liquid blend available in a wide variety of containers and delivery methods, including GE Betz’s ChemSure™ Drumless Delivery Services. Contact your GE Betz representative for details.

STORAGE

Protect from extreme temperatures. Store Spectrus NX1102 at temperatures between 40°F (4°C) and 100°F (38°C).

SAFETY PRECAUTIONS

Use of eye protection (goggles and face shield) and gauntlet-type gloves is required when handling this product. See Section 8 of the MSDS for additional information on recommended personal protective equipment.