PolyFloc AP1120P

PolyFloc AP1120P is an anionic, high charge density, high molecular weight, polymeric flocculant, which is designed to function in industrial treatment programs as a coagulant aid, or flocculant, in clarification, thickening, and sludge dewatering processes.

PolyFloc AP1120P- Anionic, High Molecular Weight Flocculant

- Cost-effective powder

- Reduces floc carryover

- Increases throughput

- Approved for potable use

DESCRIPTION AND USE

PolyFloc AP1120P is an anionic, high charge density, high molecular weight, polymeric flocculant, which is designed to function in industrial treatment programs as a coagulant aid, or flocculant, in clarification, thickening, and sludge dewatering processes.

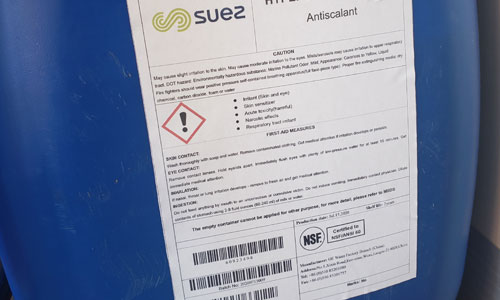

The product is NSF-certified for use in potable applications up to 1 mg/L.

PolyFloc AP1120P is a free-flowing powder, providing cost-effective solution to many solids separation processes in both influent and effluent water treatment applications.

PolyFloc AP1120P produces a fast-settling floc, which reduces carryover when used as a flocculant with inorganic or cationic polymeric coagulants.

It settles iron oxide suspensions from steel industry wastewaters and precipitate hydrous metals in finish-ing water wastes,and reduces fines in blast furnace, steel mill scale, and BOP scrubber thickener effluents.

This polymer shows excellent performance when used as an aid in protein removal on air flotation sys-tems and starch clarification with centrifuges. PolyFloc AP1120P can also be used to reduce oil in refinery and other industrial wastewaters by improving air flotation unit and API separator efficiencies.

In the steel industry and many other markets, PolyFloc AP1120P is also an excellent sludge dewatering aid producing clean filtrate, high solids capture, and a drier cake.

TREATMENT AND FEEDING REQUIREMENTS

PolyFloc AP1120P should be dissolved in water before use. The solution may be prepared in batch fashion by slowly adding the powder to the vortex of an agitated tank, using a dry powder feeder or an eductor. Do not add water to the dry polymer. Maximum practical solution concentration is 0.5% by weight. Air or low speed (350 rpm) mechanical agita-tion should continue until complete

dissolution is accomplished in about one hour.

Dissolution is accelerated with warm water, not to exceed 150°F (65°C). Avoid high shear or excessive agitation once the product has been dissolved. It is recommended that diluted solutions be used within 24 hours for maximum activity.

Further dilution of the stock solution to approximately 0.05% by weight, or a 10 to 1 ratio, enhances poly-mer performance in most applications. For dewatering applications, diluting to approximately 0.25% may be more practical. Your BetzDearborn representative can assist you in this and other polymer feeding requirements.

Diluted product may be fed by a pump, an eductor, or by gravity flow to a point where good mixing, but not violent agitation, of the treated water occurs. High speed mixing decreases the activity of the polymer. Pumps used to transfer the solution to the point of application should be positive displacement gear or piston pumps.

Liquid-side components of tanks, pumps, and piping can be constructed of stainless steel or most plastics, such as polyethylene and polypropylene. Mild steel is acceptable only in systems where contamination by corrosion products is not a critical problem. Viton and Tygon rubbers are acceptable for pump components and hose linings.