FUELSOLV OMG3911

- Slagging and fouling

- High temperature corrosion

- Cold end corrosion and fouling

- Acid smut and mist formation

- Product feed and handling

FUELSOLV OMG3911- Fireside Deposit and Corrosion Inhibitor

- Slagging and fouling

- High temperature corrosion

- Cold end corrosion and fouling

- Acid smut and mist formation

- Product feed and handling

Provides

- Better soot blowing results

- Lower costs associated with maintenance and downtime

- Boiler efficiency and reliability

- Oil-based liquid easy to feed

DESCRIPTION AND USE

FUELSOLV OMG3911 is a concentrated blend of organomagnesium in a solvent-based carrier. This product will readily disperse in an oil-based fuel and its low viscosity makes handling and feeding easy.

FUELSOLV OMG3911 works to control fireside slagging and fouling by increasing the melting point and friability of the ash constituents, making deposits easier to remove during normal soot blowing and out-ofservice cleaning FUELSOLV OMG3911 is also effective in controlling cold end corrosion and acid smutemissions.

TECHNOLOGY

Combustion related problems in boilers include slagging, fouling, high temperature corrosion, and cold end corrosion of heat transfer surfaces and other boiler components.

The deposition is related to the presence of impurities in the fuels being burned and combustion practices. High temperature deposition occurs when molten ash from the fuel impurities contacts metal surfaces of the boiler and solidifies. When this “slag” contacts the metal surface, additional ash particles are trapped in the sticky molten mass. Uncontrolled, heavy slagging and fouling will result. Once deposits form, corrosion can result beneath the deposits. Soot blowing may not be able to remove these tenacious deposits. Deposit build up results in lost efficiency and reduced throughput of the boiler. High temperature corrosion will cause metal loss and eventual tube failure.

FUELSOLV OMG3911 combines with various ash constituents to raise their melting points and weaken their deposit structure. This allows the ash to pass through the boiler as a solid and increases friability of any deposits which do form, making deposit removal easier by means of soot blowing or off-line cleaning.

Sulfur trioxide is formed from the combustion of sulfur contained in fuels. It combines with the water vapor in the flue gas to form sulfuric acid. The acid corrodes metal surfaces that are below the acid dew point. This condition is typically referred to as low temperature or cold end corrosion. In addition, the corrosion products can plug gas passages between tubes.

FUELSOLV OMG3911 combines with the vanadium to reduce the catalytic conversion of SO2 in the flue gas to SO3. Preventing the formation of SO3 in the flue gas can also result in lower stack opacity. Also,FUELSOLV OMG3911 will directly inhibit acid corrosion by neutralizing SO3 and coating the tube surfaces.

TREATMENT AND FEEDING REQUIREMENTS

Proper treatment levels for FUELSOLV OMG3911 depend on many factors such as the type of problem and severity, and the design and operating characteristics of the boiler. Therefore, this product should be used in accordance with control parameters BetzDearborn establishes for a specific application.

FUELSOLV OMG3911 should be fed by spray atomization into the furnace in an area that allows adequate distribution over the problem area. However, if this is not practical, the product can be fed with the fuel.

FUELSOLV OMG3911 should be fed neat. No recirculation system is required for this product.

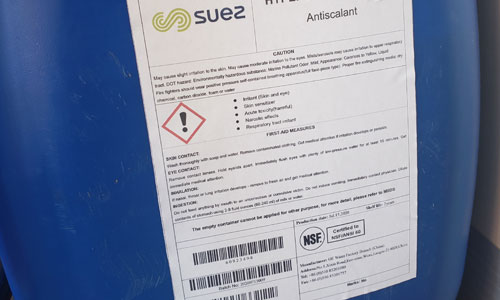

PACKAGING INFORMATION

FUELSOLV OMG3911 is available in a variety of containers and delivery methods. Contact your BetzDearborn representative for details.

SAFETY PRECAUTIONS

A Material Safety Data Sheet containing detailed information about this product is available upon Request.