Continuum AEC3175

- Controls deposition and scale with patented AEC non-phosphonate technology.

- Stable in presence of halogens.

- Maximizes deposition protection.

- Minimizes or eliminates acid feed.

- Organic Halogen Stable Azole (HRA) inhibitor for copper or copper alloy metallurgy.

- Easy and accurate MoO4Tracer.

Continuum AEC3175

Alkaline Treatment Program

- Controls deposition and scale with patented AEC non-phosphonate technology.

- Stable in presence of halogens.

- Maximizes deposition protection.

- Minimizes or eliminates acid feed.

- Organic Halogen Stable Azole (HRA) inhibitor for copper or copper alloy metallurgy.

- Easy and accurate MoO4Tracer.

Description and Use

Continuum AEC3175 is an alkaline treatment pro-gram containing Alkyl Epoxy Carboxylate (AEC). The AEC,a non-phosphonate calcium carbonate inhibi-tor, is the primary ingredient of the Continuum AEC technology and is used as a patented deposit con-trol agent. This product is the portion of a complete program that requires supplemental mild steel in-hibitor component to control corrosion and scale formation in open recirculating cooling water sys-tems over the alkaline pH range of 7.8 to 9.0 plus. The alkaline AEC programs are versatile and have been successfully used in a broad range of systems operating under variety of conditions.

AEC technology is a major breakthrough in calcium carbonate scale control. Figure 1 demonstrates the ability of AEC to inhibit calcium carbonate scale compared to other conventional inhibitors.

Organic phosphate inhibitors are susceptible to breakdown or reversion in the presence of chlorine leading to an inefficacy in carbonate inhibition. Fig-ure 2 demonstrates that there is no loss of calcium carbonate scale inhibition by AEC in the presence of chlorine. The AEC molecule is halogen stable.

This product contains the GE Betz patented Halo-gen Resistant Azole (HRA). The HRA has dramatically improved copper and mild steel corrosion rates where applied while reducing the environmental impact of the treatment program.

Treatment and Feeding Requirements

Proper treatment levels for Continuum AEC3175 depend on many factors such as the potential scaling conditions particular to a given installation. This product should be used in accordance with control procedures that GE Betz establishes for a specific application and requires either phosphate from the makeup or a supplemental inhibitor feed for mild

steel corrosion protection. Continuum AEC3175 should be fed to a point in the cooling system where it rapidly mixes with the bulk cooling water.For best results, Continuum AEC3175 should be fed neat (undiluted). Dilutions, if necessary, can only be made with low hardness water.The feed of Continuum AEC3175 is controlled by a simple and accurate Molybdate test.

Tanks, pumps,piping, and valves should be made of stainless steel,polyethylene, or PVC.

General Properties

Physical properties of Continuum AEC3175 are shown on the Material Safety Data Sheet, a copy of which is available on request.

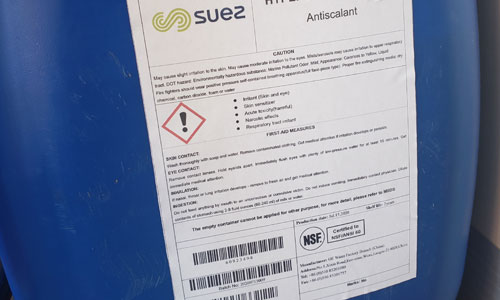

Packaging Information

Continuum AEC3175 is a liquid blend, available in a wide variety of customized containers. Contact your GE Betz representative for details.

Storage and Handling

Store Continuum AEC3175 at moderate temperatures and protect from freezing. If frozen, completely and mix thoroughly prior to use.

Safety Precautions

A Material Safety Data Sheet containing detailed information about this product is available on request.