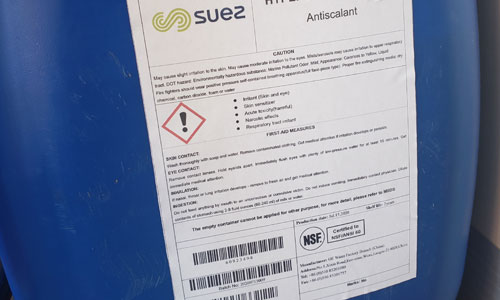

Continuum AEC3109

Continuum AEC3109

Alkaline Treatment Program

- Controls deposition and scale with patented AEC non-phosphonate technology.

- Stable in presence of halogens.

- Maximizes corrosion and deposition protection.

- Minimizes or eliminates acid feed.

DESCRIPTION AND USE

Continuum AEC3109 is an alkaline treatment pro-gram containing Alkyl Epoxy Carboxylate (AEC). The AEC,a non-phosphonate calcium carbonate inhibitor, is the primary ingredient of the Continuum AEC tech-nology and is used as a patented deposit control agent. This product is a complete program contain-ing components to control corrosion and scale forma-tion in open recirculating cooling water systems over the alkaline pH range of 7.8 to 9.0 plus. The alkaline AEC programs are versatile and have been success-fully used in a broad range of

systems operating under variety of conditions.

AEC technology is a major breakthrough in calcium carbonate scale control. demonstrates the ability of AEC to inhibit calcium carbonate scale com-pared to other conventional inhibitors.

Organic phosphate inhibitors are susceptible to breakdown or reversion in the presence of chlorine leading to an inefficacy in carbonate inhibition. Figure 2 demonstrates that there is no loss of calcium car-bonate scale inhibition by AEC in the presence of chlorine. The AEC molecule is halogen stable.

This product does not contain any copper corrosion inhibitor. Therefore, consider feeding the GE Betz patented Halogen Resistant Azole (HRA) for copper and copper alloy corrosion protection with this pro-gram. The HRA has dramatically improved copper and mild steel corrosion rates where applied while reducing the environmental impact of the treatment

program.