Belgard EV2050

Belgard EV2050 antiscalant is a high performance liquid product for the control of scaling and particulate fouling in both single and multiple effect spray film evaporators. It is a multifunctional product based on polycarboxylic acid chemistry.

Belgard EV2050 - Antiscalant and Antifoulant for Single and Multiple Effect Spray Film Evaporators

General Product Information

Belgard EV2050 antiscalant is a high performance liquid product for the control of scaling and particulate fouling in both single and multiple effect spray film evaporators. It is a multifunctional product based on polycarboxylic acid chemistry.

Belgard EV2050, with its enhanced scale control and dispersant properties is designed to give improved control of fouling throughout the plant, reducing cleaning frequencies and the associated costs.

Belgard EV2050 is particularly effective against calcium carbonate scales frequently encountered in spray film evaporators and has the additional feature of excellent dispersant activity against potential foulants suspended in the brine film. Calcium sulphate scale formation is normally prevented by avoiding supersaturation through control of brine concentration and temperature. Belgard EV2050 will give protection against calcium sulphate deposition in the event of any operating parameter excursions into the calcium sulphate supersaturation region.

Belgard EV2050 is certified to ANSI/NSF Standard 60 for use in distillation plants producing potable water.

Product Properties

The following are typical properties of Belgard EV2050 and should not be regarded as specification limits for the product. A product specification is available on request.

Appearance Pale yellow liquid

Odour Slight

pH < 2

Solids content 33 to 37% w/w

Specific gravity at 20/20oC 1.14 to 1.16

Boiling point range 101 – 103oC

Freezing point range 0 to -10 oC

Thermal Stability

Thermogravimetric analysis and differential scanning calorimetry show Belgard EV2050 to be stable up to a temperature of 200oC .

Chemical Reactivity

Belgard EV2050 is not affected by chlorine or other oxidising biocides under normal conditions of use.

Application and Dose Level

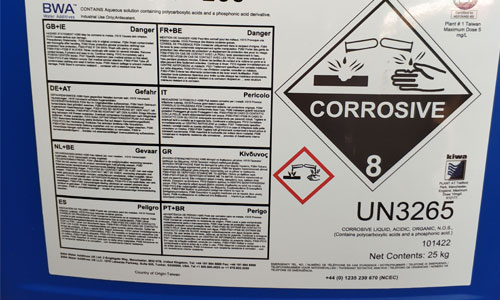

Belgard EV2050 is an aqueous solution an organic acid and as such is corrosive in its concentrated form. Corrosion resistant dosing equipment must be used – for example 316L stainless steel or plastics such as GRP, PVC or PE. In use Belgard EV2050 is immediately neutralised by the alkalinity in the recycle brine and will not contribute to the corrosion of plant materials of construction.

Belgard EV2050 is miscible with water in all proportions. It may be applied as the neat product or as a solution in distillate and should be dosed continuously and proportionately to the seawater make-up flow, to maintain the recommended dose level.

The injection point may be into the make-up line after any external de-aeration equipment. In the case of multiple-effect units additional benefit may be obtained from “split product” dosing. Additional details and recommendations are available on request.

The dose level required will depend on a number of factors, including the quality of the feed, effect temperatures and concentration factors. Typical dose levels will be in the range 2 to 5 mg/l. Detailed dose level recommendations are available on request.

Health and Safety

From the results of acute studies Belgard EV2050 is classed as non-toxic. A Material Safety Data Sheet is available on request.

Regulatory

Belgard EV2050 is certified to ANSI/NSF Standard 60 for use in seawater distillation plants producing potable water.

Logistics

Classification Corrosive for conveyance

Irritant for supply

Packaging HDPE 220L XL-ring Mauser drum

932×580 mm height x diameter

Net weight 230 kg

Gross weight 238.5 kg

Belgard EV2050 is also available in bulk, semi-bulk and 25kg net containers. Details are available on request.