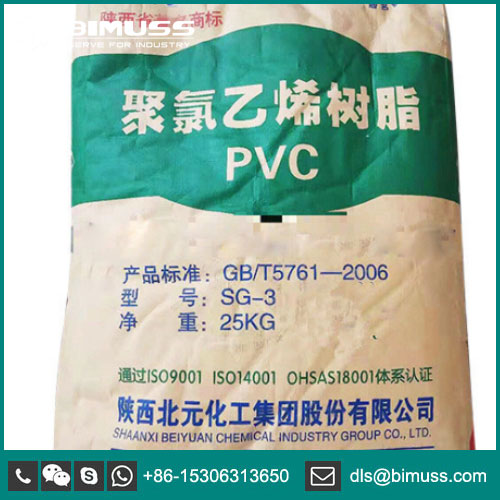

PVC resin SG3

PVC resin SG3

PVC resin SG-3 has a K value of 72-70 and an average polymerization degree of 1350-1250. It is generally used to make ordinary soft products and can be used to produce artificial leather, films, cables, shoe soles, and foam materials.

- +86 15306313650

- dls@bimuss.com

Alias | polyvinylchloride |

CAS No. | 9002-86-2 |

Chemical formula | -[CH2CHCl]-n |

EINECS | 208-750-2 |

Model No. | SG3 |

Brand | Erdos,Xinfa,Zhongtai,Sinopec |

PVC resin SG3 description

Product introduction |

PVC resin is named polyvinylchloride, and its main ingredient is PVC. In addition, other components are added to enhance its heat resistance, toughness, ductility, etc. PVC resin is a kind of synthetic material which is popular and widely used in the world.

PVC resin features and advantages |

PVC Resin with excellent fire resistance, integrated machinery, resistance to chemical corrosion, abrasion resistance,product transparency, electrical insulation and easy processing characteristics, at present, the PVC has become one of the most widely application field of plastic varieties, agriculture and daily life, in industry,packing, electric power, construction,public utilities and other fields have a wide range of applications.

Specification |

Items | Parameter |

Model No. | PVC resin SG3 |

Average degree of polymerization | 1250-1350 |

K value | 71-72 |

Viscosity | 127-135 |

Foreign particle | 16max |

Volatile matter,% | 30max |

Apparent density,g/ml | 0.48min |

0.25mm sieve retained,% | 1.0max |

0.063mm sieve retained,% | 98min |

No.of grain/400cm2 | 10max |

Plasticizer absorption of 100g resin.g | 28min |

Whiteness degree 16 ° C 10min,% | 80 |

Residual chlore thylene content,mg/kg | 1 |

Application |

Insulating material, film, shoes and etc.

Delivery information |

Package:25kg/pp bag or as the customers’ requirements

Loading capacity:18MT/20’FCL

HS Code:3904109001