Spectrus NX1103

Spectrus NX1103 is EPA approved for control of bacteria, algae, and fungi in a variety of industrial water-based systems. Spectrus NX1103 consists of a proprietary blend of 10% dodecylguanidine hydrochloride (DGH) and 5% methylene bis (thiocyanate) [MBT].

Spectrus NX1103 - Microbiological Control Agent

- Broad spectrum antimicrobial

- Proprietary blend minimizes microbial resistance

- FDA Approved (CFR 176.180 and 176.300)

- USDA Approved (G-5, G-7)

- Approved for sale in California

DESCRIPTION AND USE

Spectrus NX1103 is EPA approved for control of bacteria, algae, and fungi in a variety of industrial water-based systems. Spectrus NX1103 consists of a proprietary blend of 10% dodecylguanidine hydrochloride (DGH) and 5% methylene bis (thiocyanate) [MBT].

Spectrus NX1103 is approved for use in open recirculating cooling systems, heat exchange systems and evaporative condensers.

Control of microbiological populations in industrial water systems is essential to prevent biofouling. In cooling systems, biofouling of heat exchange equipment and tower fill reduces heat transfer efficiency and can force unscheduled shutdowns and extended turnarounds, leading to lost production. Equipment can also be damaged as a result of microbiologically influenced corrosion (MIC) associated with biofouling.Consequently, biofouling must be prevented in order for operating units to avoid such events and achieve profitability goals.

Compared to single active biocide products (see Chart), the combination of surface active agent (DGH) and metabolic inhibitor (MBT) in Spectrus NX1103 work together to provide faster microbial control at lower dosages. The blend of actives in Spectrus NX1103 also limits development of resistant microbial populations and reduces the need to alternate products to maintain effectiveness.

In addition to cooling systems, Spectrus NX1103 can be used to control microbes in influent water systems, air washers, pasteurizers, and water-based scrubbers. See the Spectrus NX1103 product label for a complete listing of approved end uses.

TREATMENT AND FEEDING REQUIREMENTS

Correct treatment levels and frequency of Spectrus NX1103 addition depend on many factors. These include, but are not limited to, system cleanliness, types of microbes, nutrient concentrations, temperature, pH, retention time, and other system operating characteristics. Consult the product label for general dosage guidelines. Microbiological monitoring is recommended to evaluate product requirements. Consult your GE Betz representative for technical advice on your specific application. In all cases, this product must be applied in accordance with use instructions on the Spectrus NX1103 label.

Feed point – Apply Spectrus NX1103 to a point in the system where turbulence and flow patterns assure good mixing with the water being treated.

Dilution – This blended product is best fed neat (undiluted) from the storage container.

Compatible Materials – Spectrus NX1103 is compatible with the following materials of construction: 316L Stainless; Hastalloy 825; High Density Cross-linked Polyethylene; Teflon; PVC; Buna N; Buna S; Ethylene Propylene Resin.

Avoid: 304 and 316, Stainless; High Density Polypropylene; Litharge Viton. This product may be fed using the PaceSetter Control system.

GENERAL PROPERTIES

Physical properties of Spectrus NX1103 are shown on the Material Safety Data Sheet, a copy of which is available on request.

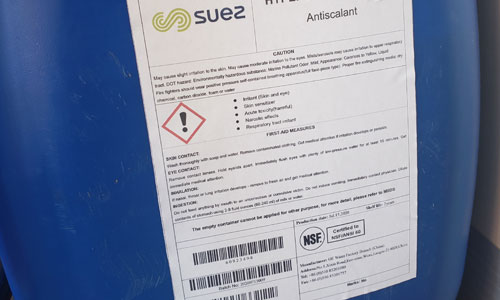

PACKAGING INFORMATION

Spectrus NX1103 is a liquid blend available in a widevariety of containers and delivery methods, including GE Betz’s ChemSureTM Drumless Delivery Services.

STORAGE

Protect from extreme temperatures. Store in a cool, ventilated location. Keep containers closed when not in use. Store away from oxidizers.

SAFETY PRECAUTIONS

Use of eye protection (goggles and face shield) and gauntlet-type rubber gloves is required when handling this product. See section 7 of the MSDS for additional information on recommended personal protective equipment.