FloGard MS801

- Mild steel corrosion inhibitors and deposit control agents for once-through/mill supply cooling systems

- Combinations of phosphate and polymer

- Custom blended one-drum treatment

FloGard MS801- Corrosion & Deposit Control for Once-Through Systems

- Mild steel corrosion inhibitors and deposit control agents for once-through/mill supply cooling systems

- Combinations of phosphate and polymer

- Custom blended one-drum treatment

DESCRIPTION AND USE

FloGard MS801 is a custom blend of phosphate and polymer designed to economically inhibit corrosion of mild steel and prevent deposition of inorganic materials in mill supply water systems and oncethrough cooling systems. FloGard MS801 does not contain any heavy metals.

If this corrosion is not controlled, iron byproducts introduced into the system can lead to numerous problems, which include reduced heat transfer, restricted water flow, deposits and sludging. These problems can seriously impede operations that the once-through cooling water is servicing. FloGard MS801 can minimize formation of corrosion products, and consequently improve operating conditions throughout the plant.

Manganese is another area of concern, as it is a tenacious deposit and has a strong affinity for yellow metallurgy, stainless steel, and plastics. FloGard MS801 is extremely effective on controlling both soluble and insoluble manganese.

FloGard MS801 provides far superior manganese and iron stabilization in comparison to competitive programs.

TYPICAL APPLICATIONS

FloGard MS801 is designed to operate over a broad temperature range in once-through and mill supply water systems, and is especially effective for controlling deposition typically generated in hot water systems. FloGard MS801 can be fed at a single location to treat the entire system and supplemental dosages may be fed in particularly troublesome areas.

TREATMENT AND FEEDING REQUIREMENTS

The treatment level for FloGard MS801 will depend on many factors such as the severity of corrosion potential and conditions particular to a given application. The product should be used in accordance with control procedures that GE Betz establishes for a specific application.

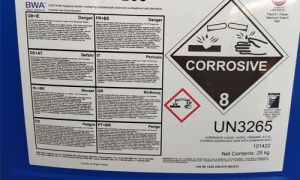

FloGard MS801 may be fed neat (undiluted) from the shipping container or diluted with low hardness water to any convenient strength.Tanks, pumps, piping and valves should be made of carbon steel, 316 stainless steel, polyethylene, or most common plastics.

Specific control procedures for each application will be established at the time treatment is initiated.

GENERAL PROPERTIES

Physical properties of FloGard MS801 are shown on the Material Safety Data Sheet, a copy of which is available upon request.

PACKAGING INFORMATION

FloGard MS801 is a liquid blend available in a wide variety of customized containers and delivery methods. Contact your GE Betz representative for details

STORAGE

Store FloGard MS801 at moderate temperatures and protect from freezing. If frozen, thaw completely and mix thoroughly prior to use.

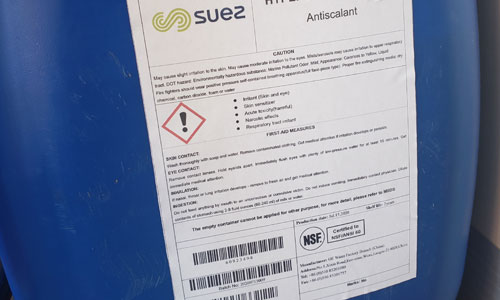

SAFETY PRECAUTIONS

A Material Safety Data Sheet containing detailed information about this product is available upon request.

PRICING

F.O.B. Destination. Minimum freight allowed.