Ferroquest LP7202

- On-line cooling system cleaning of heat exchangers, transfer tubes, and cooling tower fill

- Very rapid deposit removal

- Provides excellent removal of calcium carbonate scale deposit

Ferroquest LP7202- Deposit Removal Product

- On-line cooling system cleaning of heat exchangers, transfer tubes, and cooling tower fill

- Very rapid deposit removal

- Provides excellent removal of calcium carbonate scale deposit

- Removes co-deposits, such as calcium phosphate, silica, and magnesium salts

- Easy to apply

- Requires less time than hydroblasting

- Eliminates production downtime

- Provides more effective cleaning than HCI or H2SO4 acid cleaning

- Contains no chlorides; therefore, it is less aggressive to system metallurgy resulting in low corrosion rates during cleaning

DESCRIPTION AND USE

Ferroquest LP7202 is a unique material which removes calcium carbonate and/or calcium phosphate deposits from industrial and power cooling water systems.

These deposits must be removed because they contribute to:

- reduced heat transfer

- reduced production

- unscheduled outages

- extended turnaround schedules

TYPICAL APPLICATIONS

Typical calcium carbonate deposit removal with Ferroquest LP7202 is illustrated in Figure 1. The product also removes co-deposits, such as calcium phosphate, silica, and magnesium salts (see Figure 2).

TREATMENT AND FEEDING REQUIREMENTS

This product is designed to be utilized in two distinct manners. It can be recirculated throughout a cooling system or it can be applied using a fill-and-soak method in industrial and power equipment.

Dosage – The proper treatment levels of Ferroquest LP7202 depend on the thickness of the calcium carbonate and/or calcium phosphate deposit and the size of the system. Feed of the product is not based on system or equipment water volume. GE Betz will provide control parameters and monitoring guidelines for specific applications.

Feedpoint – If Ferroquest LP7202 is being used to clean an entire cooling system, it should be fed to the cooling tower basin in a high mix zone. If cleaning large individual pieces of equipment (i.e. a power plant condenser), feed directly to the equipment and back fill.

System Sampling – Hour samples must be taken from the cooling tower basin to accurately determine the amount of deposit removed. The amount of blowdown and makeup during the cleaning application should also be accurately measured and recorded.

System Parameters – The product can be fed to all cooling water systems except those containing galvanized metals.

It is not effective on iron, calcium sulfate, or microbiological deposits.

GENERAL PROPERTIES

Physical properties of Ferroquest LP7202 are shown on the Material Safety Data Sheet, a copy of which is available on request.

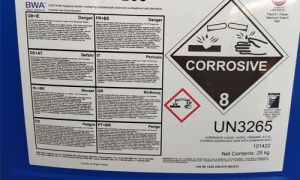

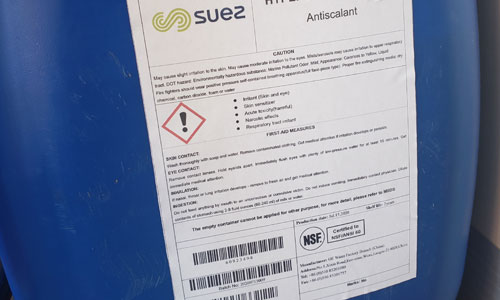

PACKAGING INFORMATION

Ferroquest LP7202 is a liquid material, available in a wide variety of customized containers and delivery methods. Contact your GE Betz representative for details.

SAFETY PRECAUTIONS

It is recommended that rubber gloves and splashproof chemical goggles be used when handling this product. A Material Safety Data Sheet containing detailed information about this product is available upon request.