CorTrol OS5035

- Controls oxygen corrosion

- Passivates preboiler and boiler surfaces

- Improves boiler reliability

- True residual test available

- Volatile oxygen scavenger contributes no solids to feedwater

CorTrol OS5035- Oxygen Scavenger

- Controls oxygen corrosion

- Passivates preboiler and boiler surfaces

- Improves boiler reliability

- True residual test available

- Volatile oxygen scavenger contributes no solids to feedwater

DESCRIPTION AND USE

CorTrol OS5035 is a 35 percent solution of hydrazine in water, designed for the control of corrosion caused by dissolved oxygen in preboiler and boiler surfaces. It is not suitable for use where the FDA or USDA regulates the boiler feedwater treatment or in drinking water systems.

TYPICAL APPLICATIONS

Even with good dearating heater operation, sufficient dissolved oxygen can remain in the feedwater to damage the boiler system. Oxygen in water produces pitting which is severe because of its localized nature.

Economaizers and feedwater preheaters are highly susceptible to oxygen attack. Because the reaction products of CorTrol OS5035 with oxygen are water and nitrogen, oxygen scavenging with product contributes no dissolved solids to the boiler water. In high purity systems, this eliminates one contributor of solids, and may reduce blowdown requirements, saving energy. In the case where feedwater is used for attemperation, the volatile nature is particularly important, since solids fed to super heaters and/or turbines may cause harmful deposits. The reducing nature of CorTrol OS5035 is exhibited by its ability to reduce a certain form of iron oxide.

This reaction can compete with the CorTrol OS5035 oxygen reaction. Under certain conditions, the product can also be beneficial in passivating copper.

TREATMENT AND FEEDING REQUIREMENTS

Feed Point – Feed CorTrol OS5035 to the condensate hot well, the deaerator storage section, or the feedwater line. Feedrate – Feed CorTrol OS5035 continuously, based on a feedwater residual test or based on the feedwater dissolved oxygen concentration. Dilution CorTrol OS5035 may be fed neat or diluted to any convenient strength with good quality condensate, demineralized water, or feedwater. Because of toxicity (see MSDS), CorTrol OS5035 is usually fedneat in a system designed to minimize operator exposure.

Equipment – Due to toxicity (see MSDS), the feed system should be designed to minimize contact with personnel. Due to incompatibility with certain organics and nitrates, CorTrol OS5035 should be fed separately from other treatment chemicals.

CorTrol OS5035 should be fed using a system as shown in Figure 1. The system features an electrically operated pump which delivers a set amount of the product to a totally enclosed day tank equipped with a conservation breather vent to minimize exposure to vapors. The product drum or semi-bulk container is provided with a vacuum breaker to prevent discharge of fumes and a quick-disconnect coupling, which seals on both sides when opened. A bill of materials with supplier contacts is provided.

GENERAL PROPERTIES

Physical properties of CorTrol OS5035 are shown on the Material Safety Data Sheet, a copy of which is available on request.

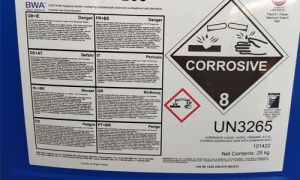

PACKAGING INFORMATION

CorTrol OS5035 is a liquid blend, available in a wide variety of customized containers and delivery methods. Contact your GE Betz representative for details.

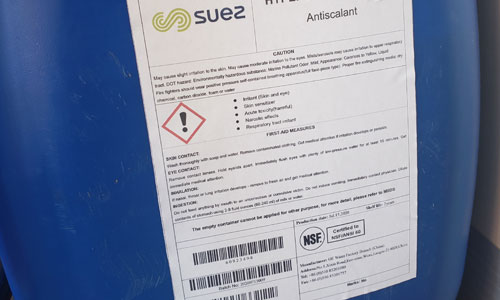

SAFETY PRECAUTIONS

A Material Safety Data Sheet containing detailed information about this product is available upon request.