CONTINUUM AT3226

- Maximizes corrosion protection without heavy metals.

- Controls deposition and scale with patented polymers.

- Eliminates or minimizes acid feed.

CONTINUUM AT3226

- Maximizes corrosion protection without heavy metals.

- Controls deposition and scale with patented polymers.

- Eliminates or minimizes acid feed.

DESCRIPTION AND USE

Continuum AT3226 is a custom designed blend which controls corrosion and scale formation in open recirculating cooling water systems. This product provides a synergistic blend of organic phosphates which is designed to minimize total phosphate required under a given set of conditions.

Continuum AT3226 incorporates a patented calcium phosphate inhibitor HPS-I. Use of this product for treatment of cooling water systems is covered by U.S. Patents 4,759,851 and 4,895,663.

TYPICAL APPLICATIONS

Continuum AT3226 is designed for cooling water systems operating in the 7.8 to 9.0 pH range. This means that systems which would normally buffer in this pH range can operate with no acid feed.

Continuum AT3226 inhibits the corrosion of mild steel. It effectively controls common scales, such as calcium carbonate and calcium phosphate, and fouling, due to iron and other suspended solids.

Continuum AT3226 is very versatile, and has been proved successful in a broad range of systems operating under widely varying conditions. The particular combination of active ingredients required to give the desired results depends on the system metallurgy, temperature, water chemistry and other system characteristics.

Before recommending an inhibitor programme, your BetzDearborn representative performs a comprehensive system survey to outline the specific operating parameters and treatment needs of your cooling systems. Using this information,the representative works with an engineer in the BetzDearborn Technical Marketing Department to select a specific formulation to meet the needs of your system.

TREATMENT AND FEEDING REQUIREMENTS

Dosage – The proper treatment level of Continuum AT3226 depends on the individual needs of your system. The product should be fed in accordance with control parameters that BetzDearborn establishes for the particular application. For consistent protection, continuous feed is recommended.

Feed point – Continuum AT3226 should be fed to a point in the cooling system where it can rapidly mix with the bulk cooling water.

Dilution – For best results, Continuum AT3226 should be fed neat. Dilutions, if necessary, are best made with low hardness water.

Feed Equipment – Tanks, pumps, piping and valves should be made of mild steel, stainless steel, polyethylene or most common plastics.

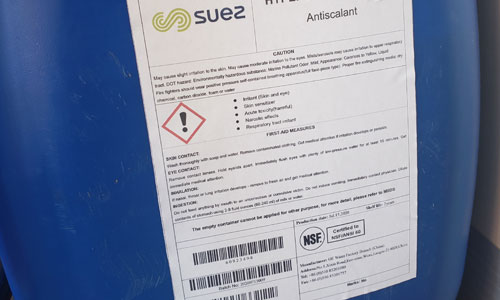

SAFETY PRECAUTIONS

Material Safety Data Sheets containing detailed information relative to this product are available upon request.

SHIPPING INFORMATION

Continuum AT3226 is blended as a liquid and is typically supplied under the Betz Point of Feed and Betz Semi-Bulk Control delivery programs.

STORAGE INFORMATION

Store Continuum AT3226 products at moderate temperatures and protect from freezing. If frozen, thaw completely and mix thoroughly prior to use.