Continuum AEC3110

- Patented AEC phosphonate free technology to control deposition and scaling.

- Achieve maximum corrosion and deposition control.

- Organic halogen-resistant azole, inhibition of copper and copper alloy corrosion.

Continuum AEC3110

Product features

- Patented AEC phosphonate free technology to control deposition and scaling.

- Achieve maximum corrosion and deposition control.

- Organic halogen-resistant azole, inhibition of copper and copper alloy corrosion.

Application

Aec3110 is an alkaline treatment scheme containing alkyl epoxy carboxylates (AEC). Alkyl epoxy carboxylate (AEC) is a kind of CaCO3 inhibitor of non organic phosphonate. In the open circulating cooling water system with pH value of 7.8-9.0, the product needs to be supplemented with sufficient corrosion inhibitor to control corrosion and scaling. The basic AEC scheme has wide applicability and has been successfully used in various operating systems under different conditions.

Usage and dosage

The proper dosage of aec3110 depends on many factors, such as potential scaling conditions, especially under given installation conditions. Aec3110 should be directly added (without dilution). If dilution is necessary, use only low hardness water. Our technicians will provide you with detailed instructions and technical guidance.

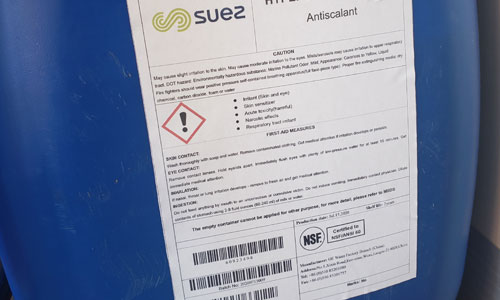

Packaging and storage

It should be packed in plastic drums, 25kg per barrel or determined according to the user’s requirements; it should be stored at medium temperature to avoid freezing. If it has been frozen, it should be thoroughly thawed and fully mixed before use. The storage period is 12 months.

Safety protection

When the product is added, avoid contact with skin and eyes, and rinse with plenty of water after contact.