Continuum AEC3189

Continuum AEC3189 is a phosphate source to be used with Continuum AEC programmes, these are synergistic blends designed to control corrosion and scale formation in open evaporative cooling systems.

Continuum AEC3189

Provides a source of phosphate

DESCRIPTION AND USE

Continuum AEC3189 is a phosphate source to be used with Continuum AEC programmes, these are synergistic blends designed to control corrosion and scale formation in open evaporative cooling systems.

Continuum AEC programmes incorporate the patented calcium phosphate inhibitor GE Betz HPS-I and the patented AEC (Alkyl epoxy carboxylate) molecule. AEC provides superior calcium carbonate protection, especially in high hardness, high alkalinity and high temperature systems that have suffered from scale when treated with traditional technologies.

GE Betz’s Continuum AEC cooling treatment programmes are designed for alkaline open recirculating cooling systems.

TYPICAL APPLICATIONS

Continuum AEC programmes are designed for cooling systems operating at alkaline pH, typically pH 8.0 or above.

This means that acid feed, and the costs and concerns associated with acid dosing, may be reduced or eliminated.

Continuum AEC programmes inhibit the corrosion of mild steel, copper and its alloys. They effectively control common scales, such as calcium carbonate and calcium phosphate, and fouling due to iron and other suspended solids.

The particular combination of active ingredients required to give the desired results depends on the system metallurgy,temperature, water chemistry and other system characteristics.

The azole provides protection to copper bearing alloys, this mild steel protection by reducing galvanic corrosion induced pitting.

Before recommending a Continuum AEC product, your GE Betz representative performs a comprehensive system survey to outline the specific operating parameters and treatment needs of your cooling system(s).

Using this information the representative works with their Management and Technical Team to design and select the specific

Continuum AEC formulation to meet the needs of your system.

TREATMENT AND FEEDING REQUIREMENTS

Dosage – The product should be fed in accordance with control parameters that GE Betz establishes for the particular application.

For consistent protection, continuous feed is recommended.

Feed point – Continuum AEC products should be fed to a point in the cooling system where they can rapidly mix with the bulk cooling water.

Dilution – For best results, Continuum AEC products should be fed neat. Dilutions, if necessary, are best made with low hardness water.

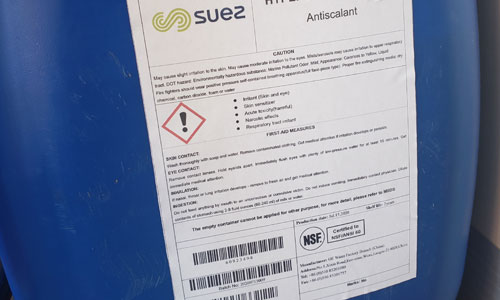

SAFETY PRECAUTIONS

Safety information is provided on the Product Label and Material Safety Data Sheets.